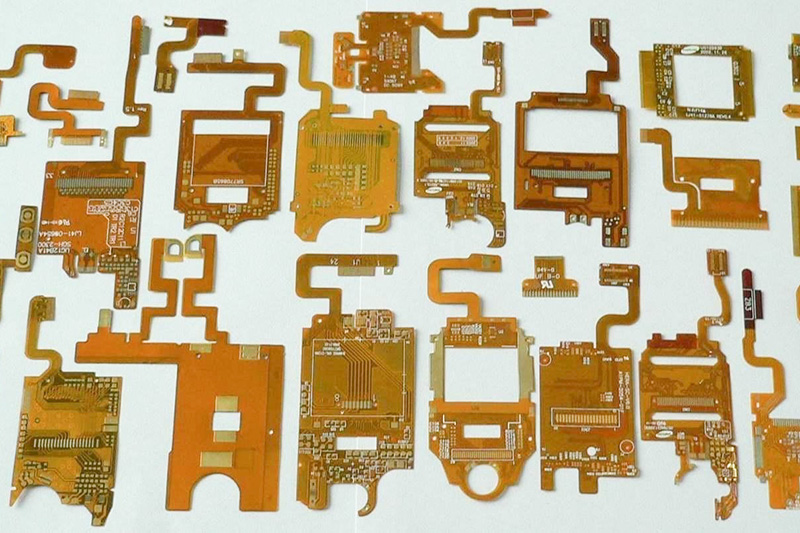

Flexible feeding technology is widely used in the field of industrial automation due to its flexibility and efficiency, especially suitable for handling materials with complex shapes, fragility, or requiring high-precision positioning.

To solve the difficult problems of traditional feeding methods for customers, make product feeding modular and flexible, switch materials faster, improve the compatibility and versatility of the feeding platform, and reduce the cost of comprehensive feeding equipment.

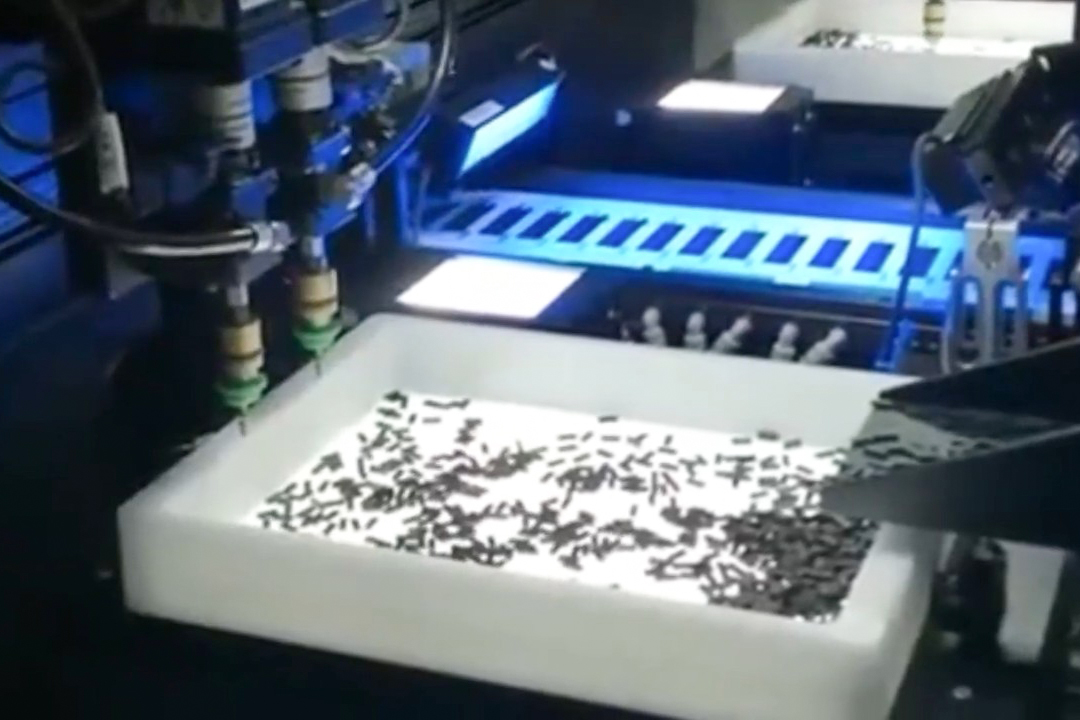

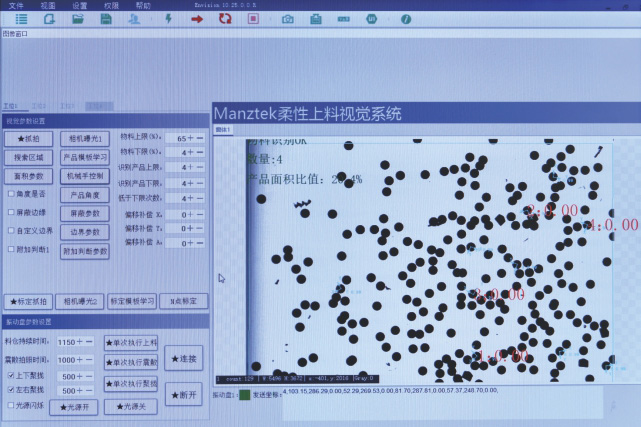

The flexible vibrating plate has a built-in control system, which occupies a small space, the disassembly of the material plate is quick, the installation and operation are convenient, the amplitude is strong, and the action effect is good. The vision part is responsible for detecting automatic feeding and robot positioning and grabbing when materials are in short supply.

The flexible vibrating plate mainly includes a frame body and a feeding tray, and the frame body mainly plays a supporting and fixing role. The frame body is mainly composed of a bottom plate, a voice coil motor module (consisting of at least one motor base and at least one voice coil motor), a cover plate and a flexible vibration disk controller.

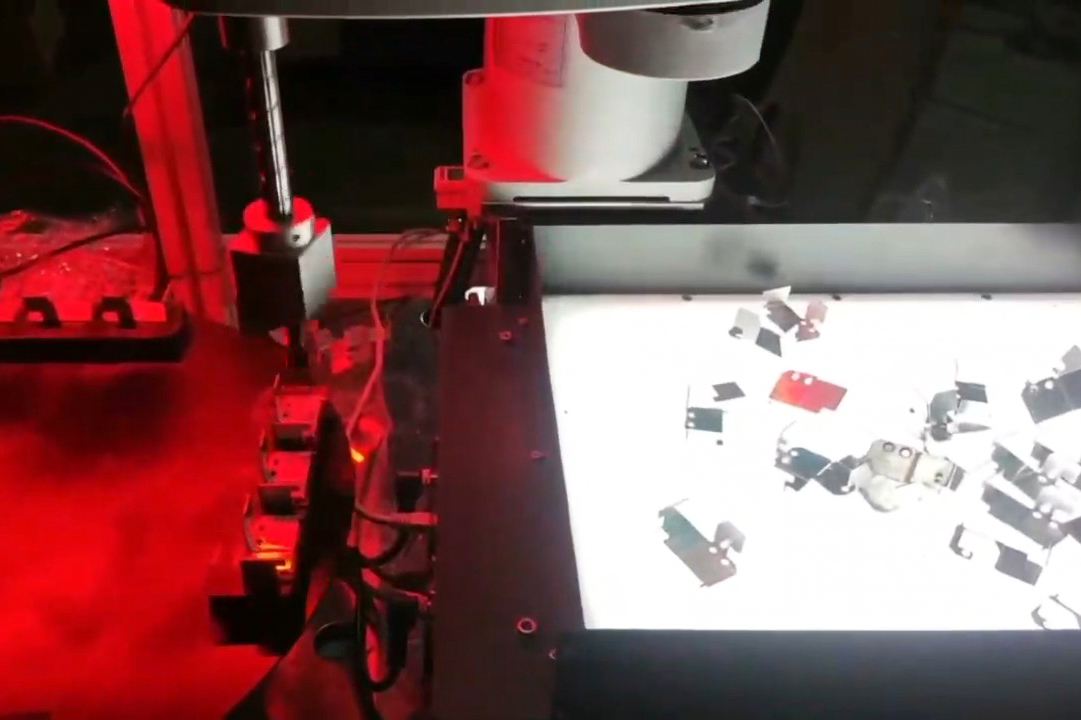

The core of the flexible visual material selection is to use the robot 3D visual positioning system, based on the principle of triangulation, to obtain the point data of the workpiece through the rapid scanning of the stereo camera, to carry out 3D modeling of the point data, and to intelligently carry out the modeling features.

With the gradual popularization of flexible feeding of small parts, more and more manufacturers enjoy the convenience and economy brought by flexible feeding. At the same time, users often call to ask if XXX products can be detected? Such questions can be summed up as: What geometries can flexible loading detect?