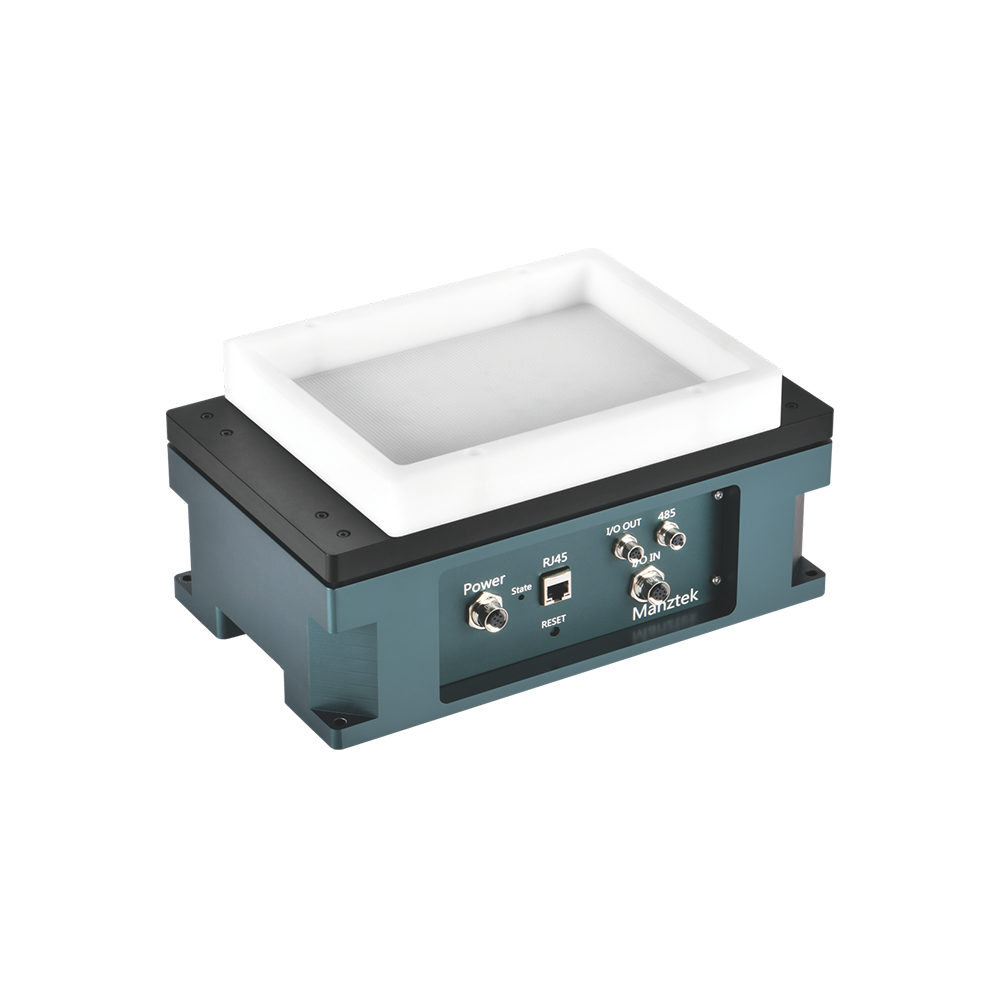

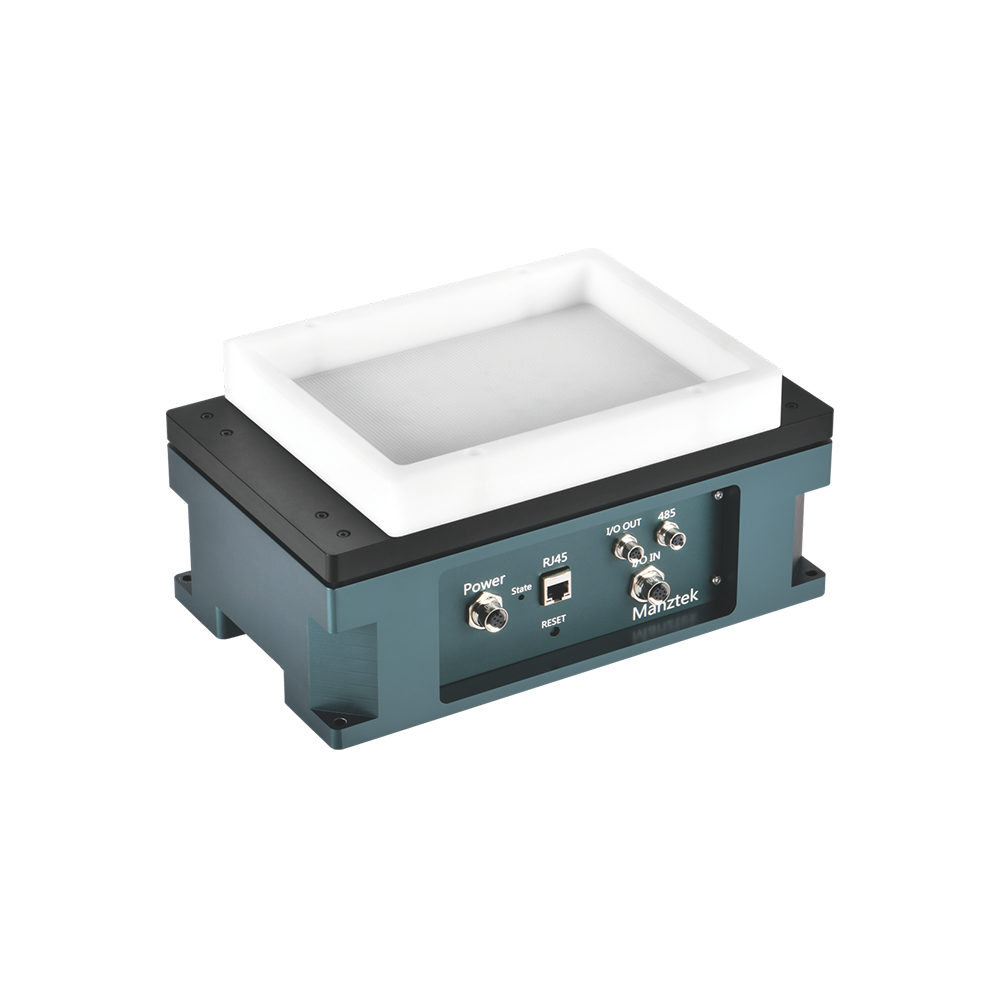

| Dimension (L*W*H) | 235*132*131(mm) |

| Plate inner size | 118*160(mm) |

| Plate sidewall height | Standard 26mm, 19mm (customizable) |

| Weight | 9kg |

| Work voltage | DC24V/8A |

| Vibration frequency | The working frequency of the same type of vibrating plate is exactly the same, and the working frequency of different materials is exactly the same |

| Idle run noise | ≤65db |

| Max. load | 0.5kg |

| Max weight of flipable workpiece | ≤30g |

| Cycle time of single action | 150-300ms |

| Movement model | Vibrate vertically, gather, move around in one direction |

| Back light | Built-in white backlight with adjustable brightness |

| Control driver board | Built-in driver, circuit isolation, input and output NPN, EMC, multi-wave type control |

| Communication & interface | TCP/IP passive IO |

| Modular design All-aluminum modular body, motor, backlight, feed bin direct vibration drive control integrated design |

| Simple application Complete vibration debugging and parameter setting within 5 minutes, support network port communication and passive IO control |

| Product standardization The whole system comes standard with TOMITION voice coil motor, the motor life is more than 5 years, and the vibration parameters of the same type of vibration plate are exactly the same |

| High stability and security DC24V system, electrical isolation, EMC, multi-waveform combination control, no-load noise less than or equal to 65 decibels |

Application areas: electronics, hardware, plastics, clocks, batteries, food, connectors, medicine, food, toys, stationery, semiconductors, magnetic cores, FPC and other industries.

Applicable shapes: irregular shapes such as sheet, 0, U, L, needle, granule, strip, square, cylinder, tower, cone, etc.

Applicable materials: plastic parts, hardware parts, rubber parts, electronic parts, ceramic parts, silicone parts, stamping parts and other small composite parts.

Applicable materials: springs, USB heads, buttons, snaps, wire harnesses, gaskets, silver contacts, connectors, coils, O-rings, bottle caps, line cards, silicone, skeleton, thimble, positioning pins, antennas, capacitors , Connectors, pin headers, female headers, terminals, dome shrapnel, angle valves, blades, zippers, etc.

Special requirements: surface coating easily damaged parts, oily parts, electroplating parts, etc.

|  |  |

| Special-shaped spring automatic flexible feeding | Flexible feeding of special-shaped precision parts | Flexible feeding of powder metallurgy special-shaped plastic parts |

|  |  |

| Gasket flexible feeding | Mascara flexible feeding | Flexible feeding of mobile phone parts |

|  |  |  |

|  |  |  |