The size of the MZ-F90 disk is 111X71mm, which is suitable for fine parts of 0.1-2mm. The silo and the flexible disc are integrated in one design, the structure of the whole machine is more compact, and the combined installation is simpler and more beautiful; the weight of the reversible material is less than or equal to 5g, which fully meets the fine and small characteristics of fine parts; the disc surface is made of rigid material race steel, which has good wear resistance. The stability makes the fine and tiny parts not easy to be damaged and improves the yield; the vibration response time is as short as 100-300 ms to complete the vibration dispersion. Parts are automatically aligned.

The size of the MZ-F120 disk is 120X89mm, which is suitable for fine parts of 0.1-5mm. The silo and the flexible disc are integrated in one design, the structure of the whole machine is more compact, and the combined installation is simpler and more beautiful; the weight of the reversible material is less than or equal to 5g, which fully meets the fine and small characteristics of fine parts; the disc surface is made of rigid material race steel, which has good wear resistance. The stability makes the fine and tiny parts not easy to be damaged and improves the yield; the vibration response time is as short as 100-300 ms to complete the vibration dispersion. Parts are automatically aligned.

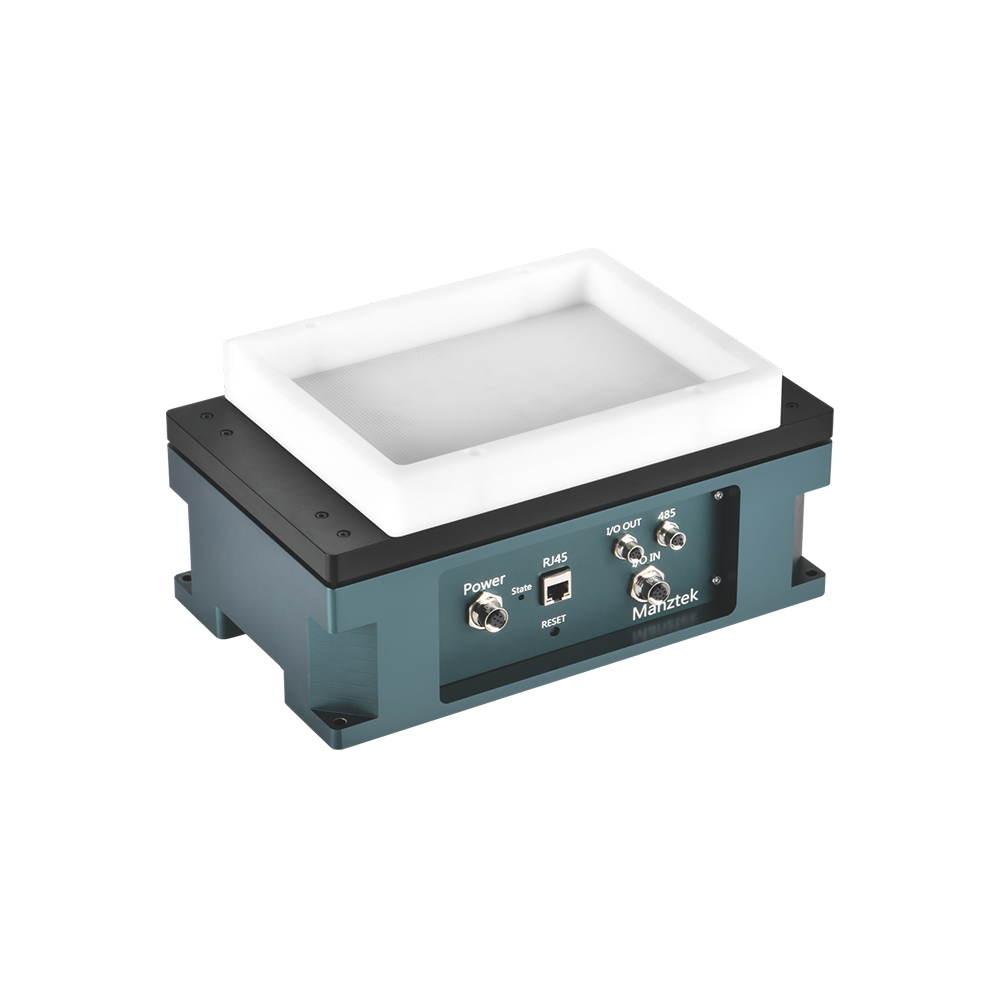

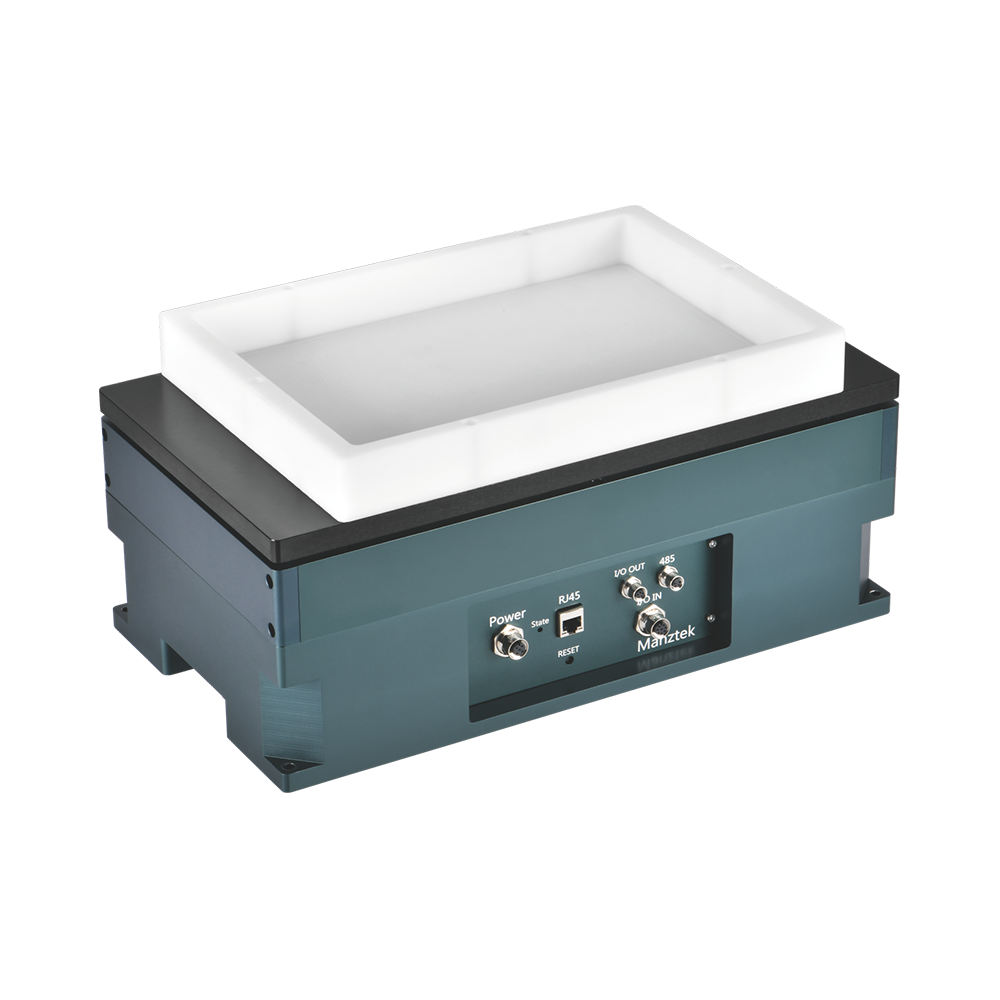

The size of the MZ-F150 disk is 160X118mm, which is suitable for fine parts of 3-10mm. The structure of the whole machine is modular, and the combined installation is simpler and more beautiful; the weight of the reversible material is less than or equal to 30g, which fully meets the fine and small characteristics of fine parts; the disk surface is made of rigid material race steel, and the good wear resistance makes the fine and small parts not easy to be damaged. Yield rate; the vibration response time is as short as 100-300 ms to complete the vibration dispersion, and the customized material tray (holes, grooves, teeth, wire drawing) based on the shape and structure of the parts is convenient for the automatic orientation and arrangement of disorganized parts.

MZ-F200 disk size is 208X156mm, suitable for fine parts of 5-15mm. The structure of the whole machine is modular, and the combined installation is simpler and more beautiful; the weight of the reversible material is less than or equal to 30g, which fully meets the fine and small characteristics of fine parts; the disk surface is made of rigid material race steel, and the good wear resistance makes the fine and small parts not easy to be damaged. Yield rate; the vibration response time is as short as 100-300 ms to complete the vibration dispersion, and the customized material tray (holes, grooves, teeth, wire drawing) based on the shape and structure of the parts is convenient for the automatic orientation and arrangement of disorganized parts.

MZ-F300 disk size is 280X210mm, suitable for fine parts of 10-25mm. The structure of the whole machine is modular, and the combined installation is simpler and more beautiful; the weight of the reversible material is less than or equal to 50g, which fully meets the fine and small characteristics of fine parts; the disk surface is made of rigid material race steel, and the good wear resistance makes the fine and small parts not easy to be damaged. Yield rate; the vibration response time is as short as 100-300 ms to complete the vibration dispersion, and the customized material tray (holes, grooves, teeth, wire drawing) based on the shape and structure of the parts is convenient for the automatic orientation and arrangement of disorganized parts.

MZ-F400 disk size 336X265mm, suitable for 25-40mm fine parts. The structure of the whole machine is modular, and the combined installation is simpler and more beautiful; the weight of the reversible material is less than or equal to 50g, which fully meets the fine and small characteristics of fine parts; the disk surface is made of rigid material race steel, and the good wear resistance makes the fine and small parts not easy to be damaged. Yield rate; the vibration response time is as short as 100-300 ms to complete the vibration dispersion, and the customized material tray (holes, grooves, teeth, wire drawing) based on the shape and structure of the parts is convenient for the automatic orientation and arrangement of disorganized parts.