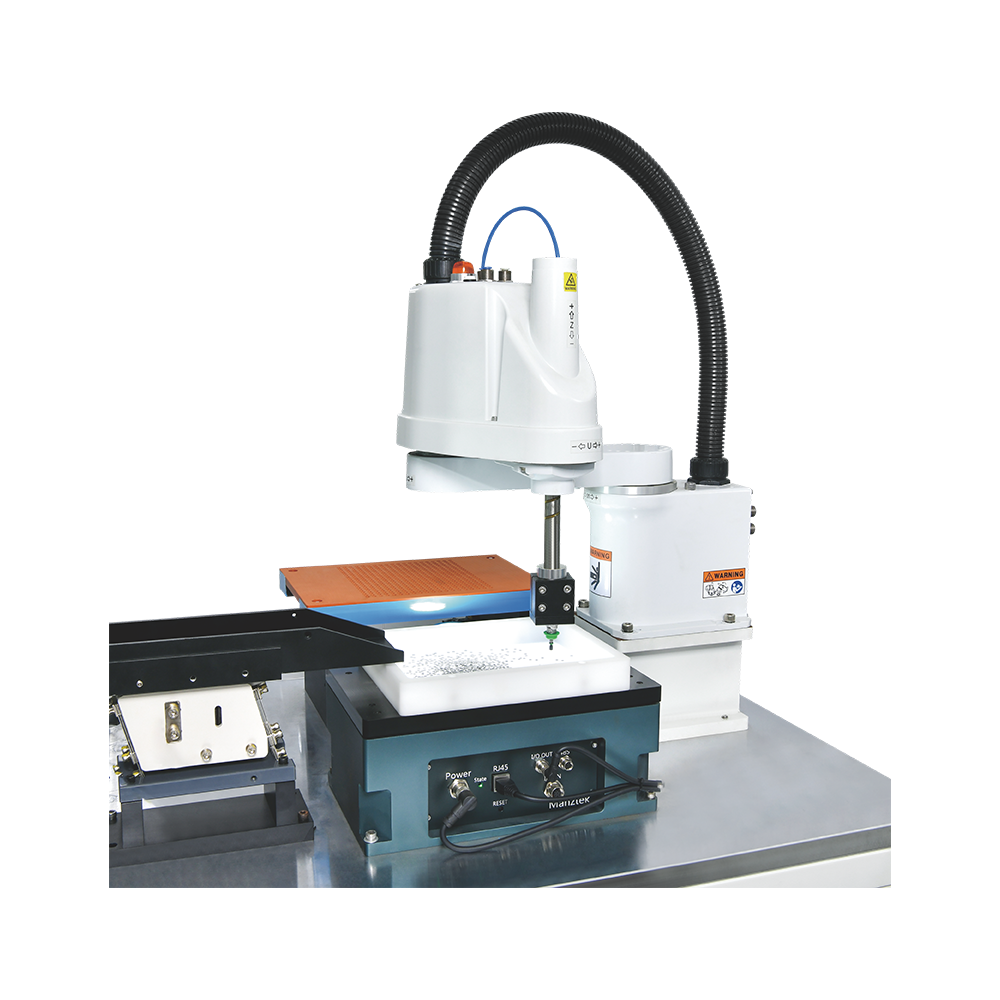

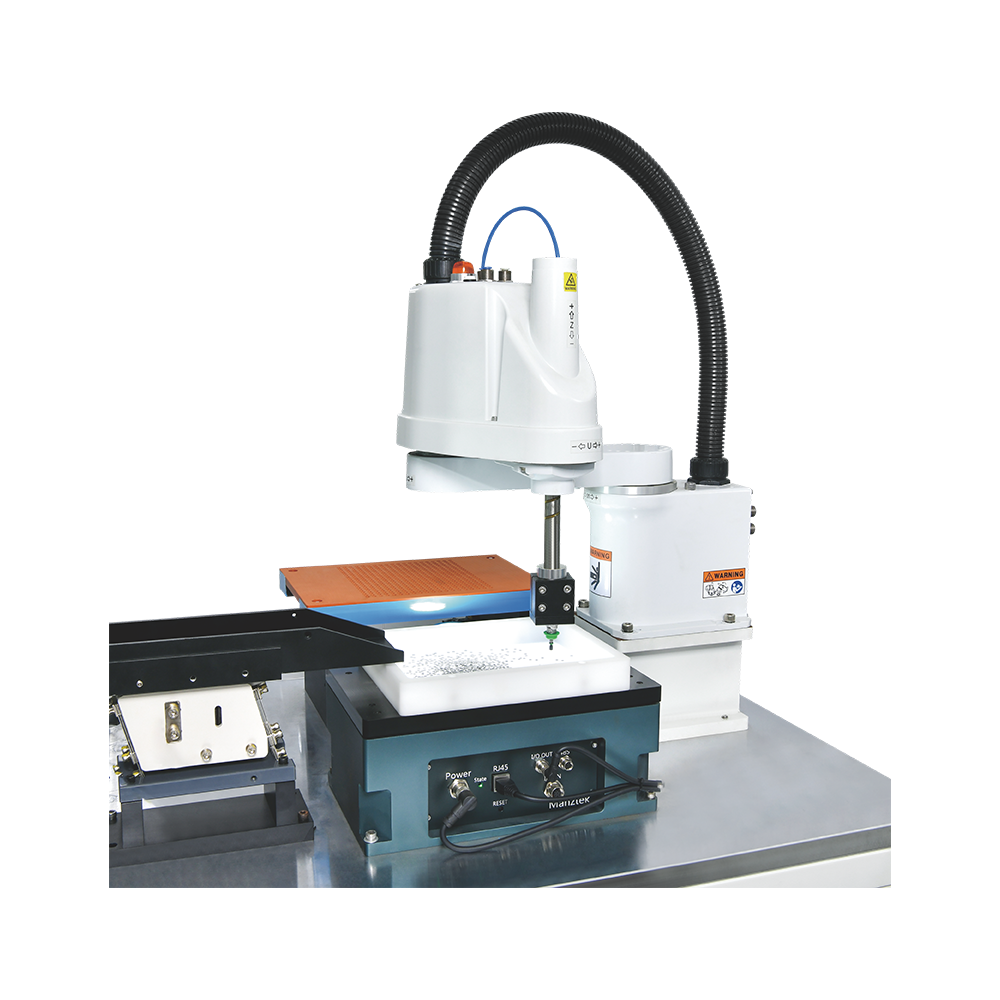

Manztek Feeder loading station's feature

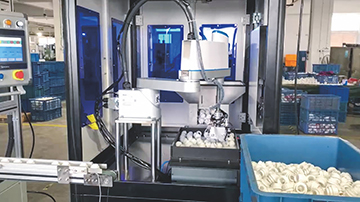

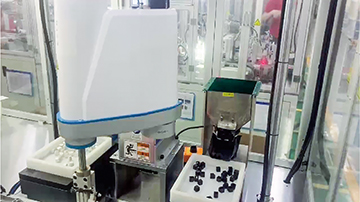

| Wide Application Applicable to a variety of parts, complex geometric shapes, surface coatings that are afraid of scratches, flakes, and special-shaped parts |

| Flexible Production Can realize multi-variety sharing and fast material switching |

| Low noise,no wear on workpiece No cyclic vibration of materials, no wear on materials, low noise, and no risk of material jamming |

| High precise positioning Independent research and development of industrial visual positioning technology, high-precision positioning and grasping |

| Visual management system The self-developed visual grasping system can store the material selection and configuration procedures of various materials, without the need for tedious installation and debugging, and one-click to complete the variety switching |

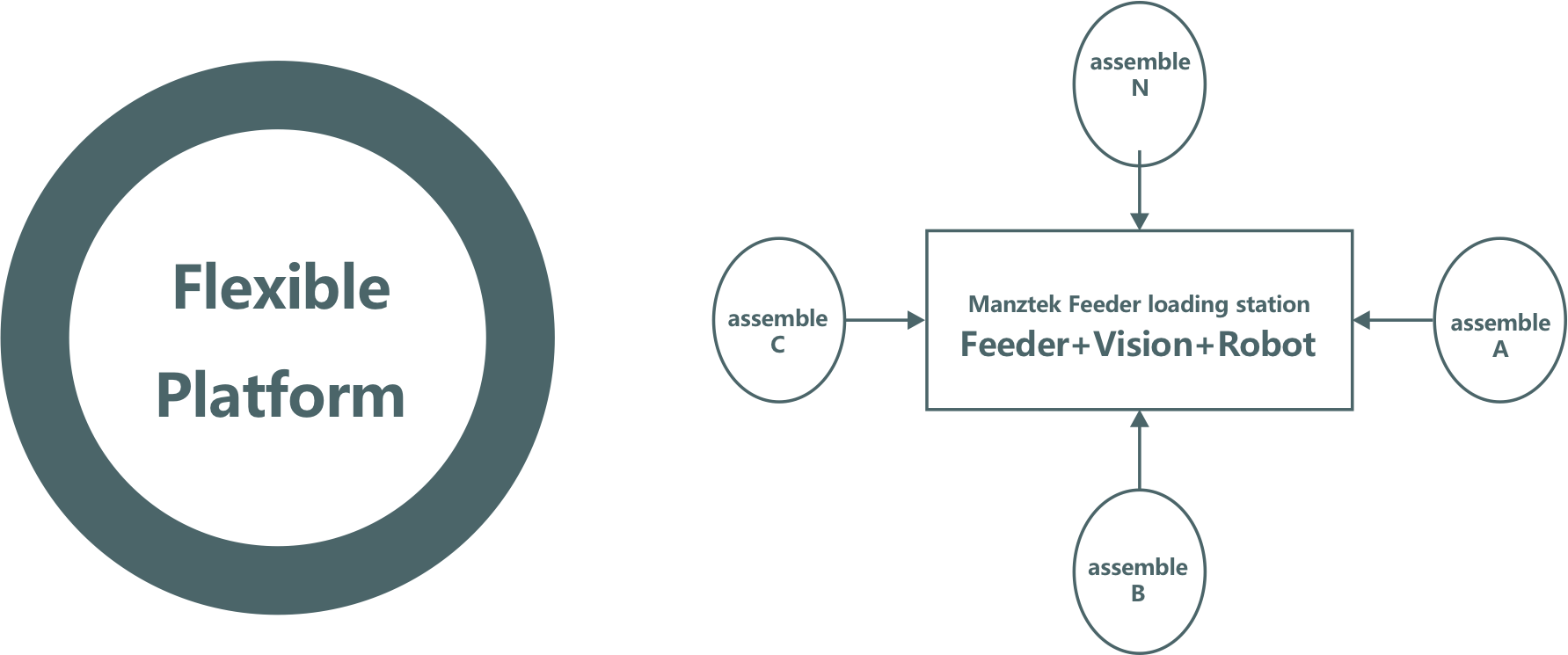

Flexibility is the direction of automation equipment

Strong versatility

It can integrate the whole system from single-station multi-product to multi-station assembly, and achieve the goal of fully automatic flexible feeding through a set of flexible custom-designed system solutions.

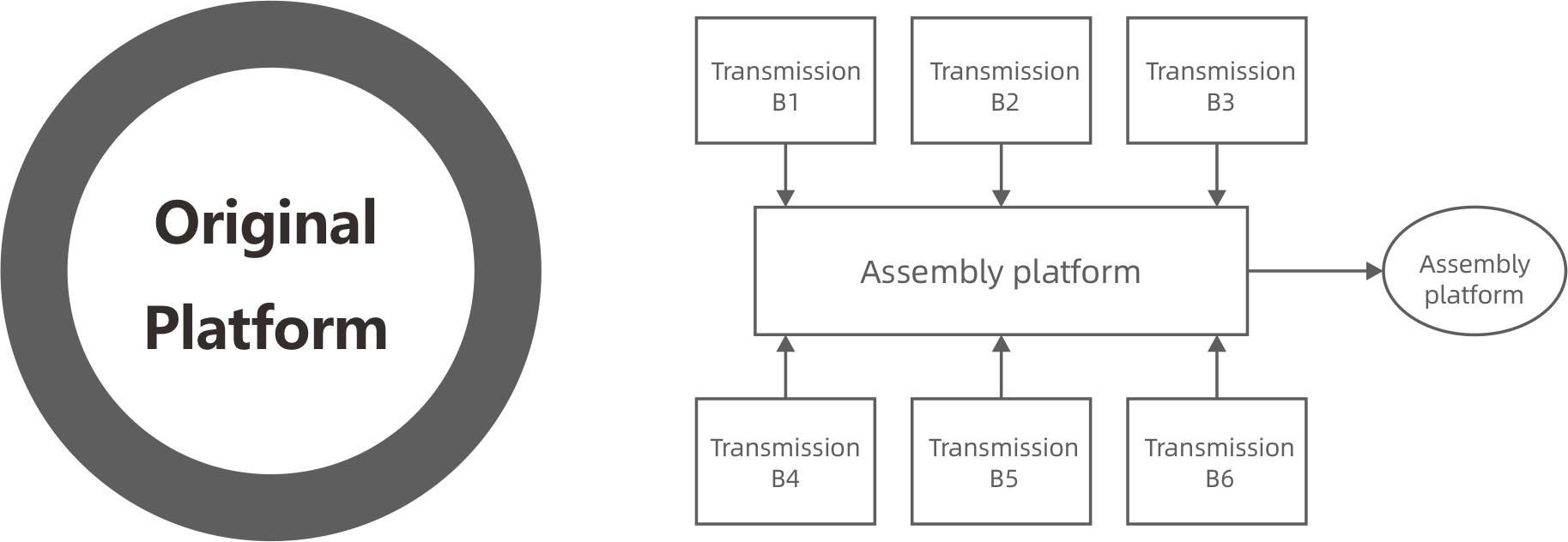

Not universal Each material requires a custom circular vibrating disc, and each vibrating disc has an endless risk of jamming and no reusability.

The customer has 6 categories of products from B1-B6 to be produced, so the production line layout is at least 6 assembly production stations. Among them, Class A or other types of products are composed of 10-12 parts and components of different sizes and shapes and materials (metal/plastic). According to the design concept of the traditional production line, each individual station needs 10-12 vibrating plate feeding modules to meet all the product feeding and assembly requirements of the station; then the entire 6-station production line requires at least 60 -70 traditional vibrating plate feeding modules to achieve.

| Modular design All-aluminum modular body, motor, backlight, feed bin direct vibration drive control integrated design |

| Simple application Complete vibration debugging and parameter setting within 5 minutes, support network port communication and passive IO control |

| Product standardization The whole system comes standard with TOMITION voice coil motor, the motor life is more than 5 years, and the vibration parameters of the same type of vibration plate are exactly the same |

| High stability and security DC24V system, electrical isolation, EMC, multi-waveform combination control, no-load noise less than or equal to 65 decibels |

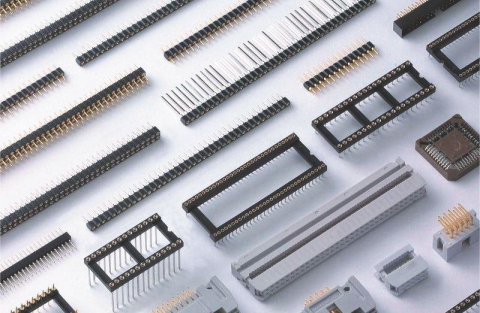

Application areas: electronics, hardware, plastics, clocks, batteries, food, connectors, medicine, food, toys, stationery, semiconductors, magnetic cores, FPC and other industries.

Applicable shapes: irregular shapes such as sheet, 0, U, L, needle, granule, strip, square, cylinder, tower, cone, etc.

Applicable materials: plastic parts, hardware parts, rubber parts, electronic parts, ceramic parts, silicone parts, stamping parts and other small composite parts.

Applicable materials: springs, USB heads, buttons, snaps, wire harnesses, gaskets, silver contacts, connectors, coils, O-rings, bottle caps, line cards, silicone, skeleton, thimble, positioning pins, antennas, capacitors , Connectors, pin headers, female headers, terminals, dome shrapnel, angle valves, blades, zippers, etc.

Special requirements: surface coating easily damaged parts, oily parts, electroplating parts, etc.

|  |  |

| Special-shaped spring automatic flexible feeding | Flexible feeding of special-shaped precision parts | Flexible feeding of powder metallurgy special-shaped plastic parts |

|  |  |

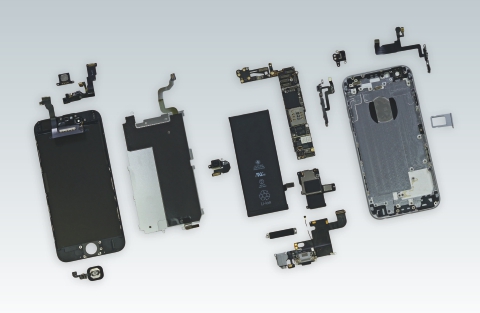

| Gasket flexible feeding | Mascara flexible feeding | Flexible feeding of mobile phone parts |

|  |  |  |

|  |  |  |