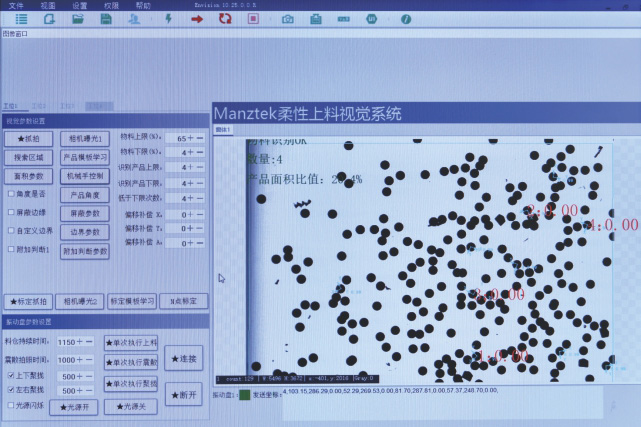

With the gradual popularization of flexible feeding of small parts, more and more manufacturers are enjoying the convenience and economy brought by flexible feeding. At the same time, users often call to ask if XXX products can be detected? Such questions can be summed up as: What geometries can flexible feeding detect?

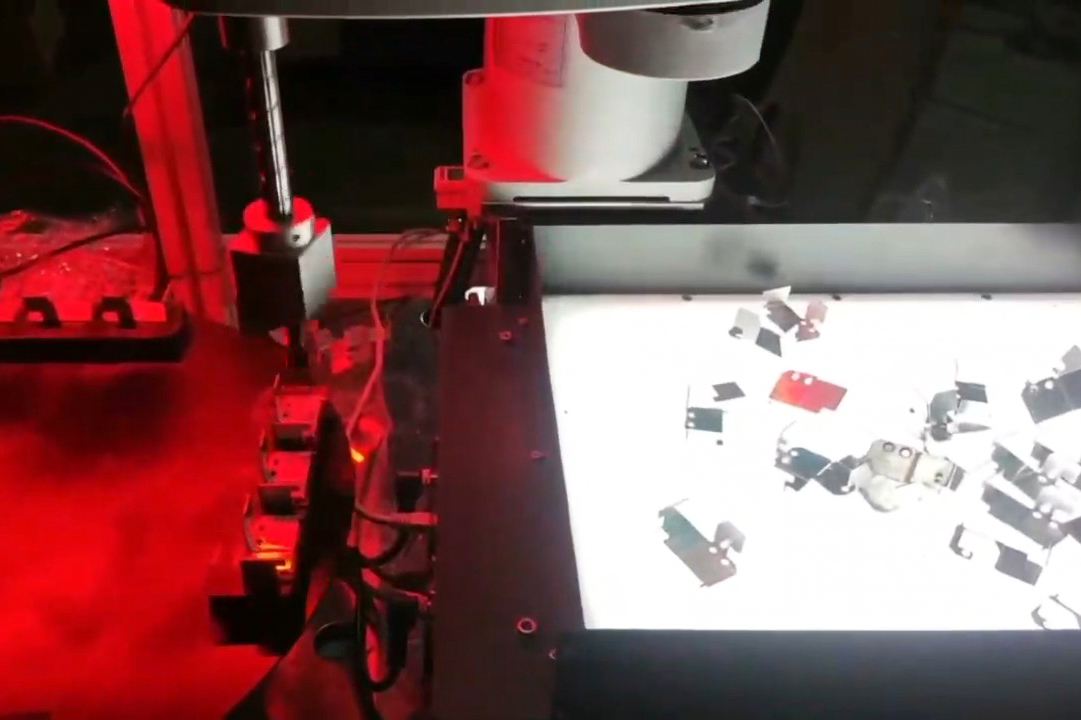

The shape of the product suitable for flexible feeding of small parts can be varied. In theory, as long as the upper and lower end faces are flat (or one side is flat and the other side is a curved surface with a small curvature), visual inspection can be used. Why is the end face required to be flat? There are two reasons, one is the feeding problem, the product must be placed on the tray with the plane facing down, otherwise it will shake left and right and affect the detection. Another reason is that the non-planar appearance inspection will be limited by the principle of the optical path, resulting in unsatisfactory imaging of the appearance station camera, and ultimately resulting in low accuracy of appearance inspection. In addition to requiring the upper and lower end faces to be flat, there are also certain requirements for the aspect ratio of the product, that is, the flatter the better. Because the product with an excessively large aspect ratio has a high center of gravity during vertical feeding, it is easy to be unable to stand on the tray, so it may not be able to be detected smoothly.

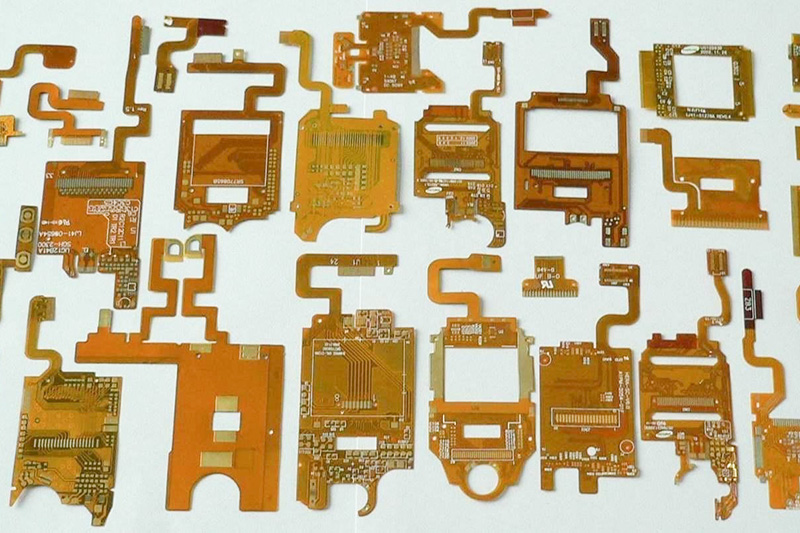

oSquare ring C angle/square ring R angle/D type C angle type, these three types are generally used on mobile phones, the earliest is the square ring R angle, later changed to the square ring C angle, and later evolved into asymmetrical The D-type C angle. Due to the thin product thickness (generally between 0.5mm-1mm), cracks are prone to appear at the corners during processing, and cracks are the main detection content; in terms of size, focus on the inspection of the inner hole symmetry.

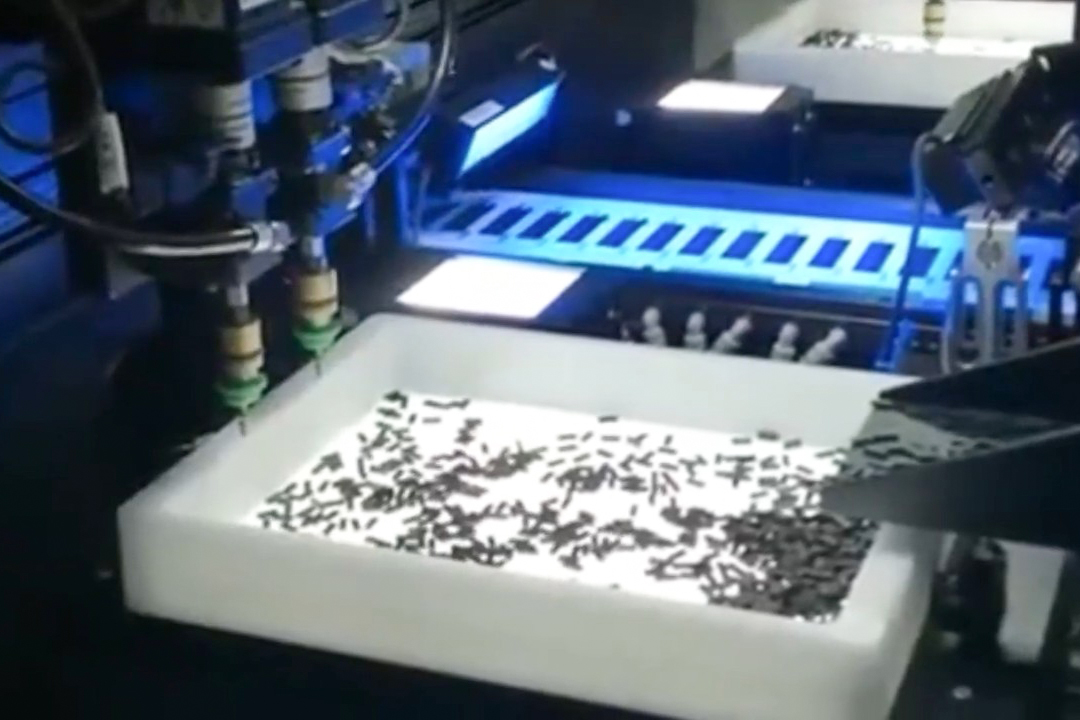

oT1/T2/T3 type, the common feature of these sheet shapes is long strip, the difference is that the shape of the end face is different, the end face of T type is an elongated "convex" character, and the end faces of T2 and T3 types are hexagonal trapezoid and isosceles trapezoid. Due to the small width of these products and different processing in the width direction, size detection is the focus and difficulty of this type of product. Another difficulty in automatic detection is the feeding problem. Some product specifications are very close in width and thickness direction, which requires the feeding accuracy of the feeder to be high enough, and Daniel's flexible visual feeding can easily deal with this type of product. Feeding

o Outer square inner circle type, also known as square punching, is characterized in that the center point of the square and the center of the inner hole are coincident. The outer square is round and the inner circle is more impressive. It is a product adopted by the Apple mobile phone iPhone 6s. The characteristics of this product are that the three dimensions of length, width and thickness are very similar. This requires the visual robot to be able to feed materials according to a variety of different attitudes.

oCross-shaped, the characteristic of the cross-shaped is that the key dimensions are concentrated on the side, so to accurately measure these key dimensions, the workpiece must be erected to measure, which is another big challenge to the feeding technology.

o Trapezoid/Hexagonal Trapezoid/Yuanbao, these three types of zoom motors commonly used in smartphone cameras or digital cameras, are characterized by very small product size, generally the maximum size is less than 4mm, and the shape is more complex. Because the product size is too small and the shape is complex, manual detection is very difficult and the efficiency is very low.